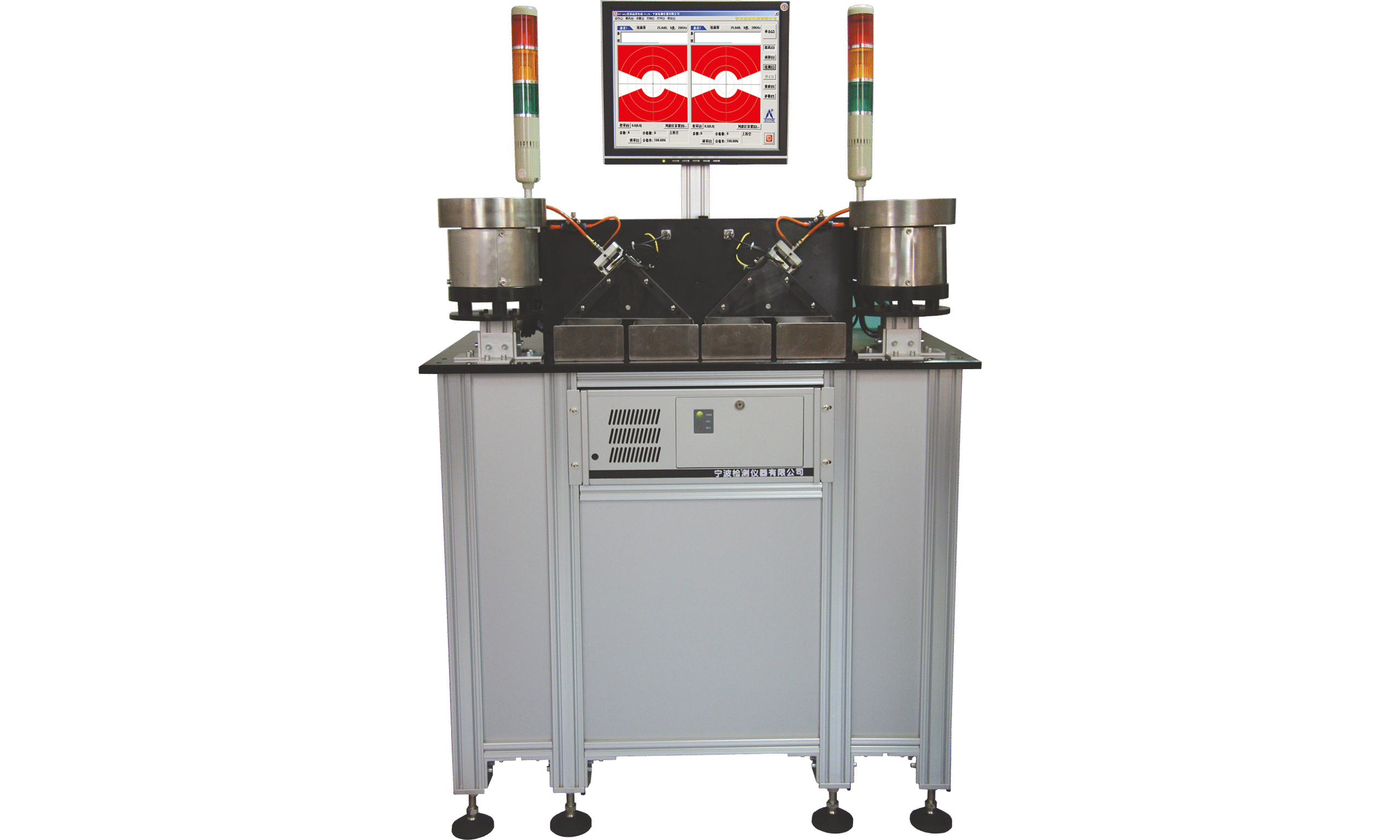

WT-632 Integrated Eddy Current Testing Machine detect flaws on the OD and unqualified hardness of cylinder rollers. Suitable for the parts which need both flaw detection and hardness sorting.

Main features:

- Two separate channels. One for flaw detection, one for hardness sorting.

- Detection sensitivity: ≥0.05mm length, ≥2mm depth cracks. ≥

- Speed: 2 secs/piece.

- Automatic loading, selecting, counting and unloading.

- No damage after detection.

- Detect without demagnetization.

- Statistics total number, qualified number, qualified rate, etc.